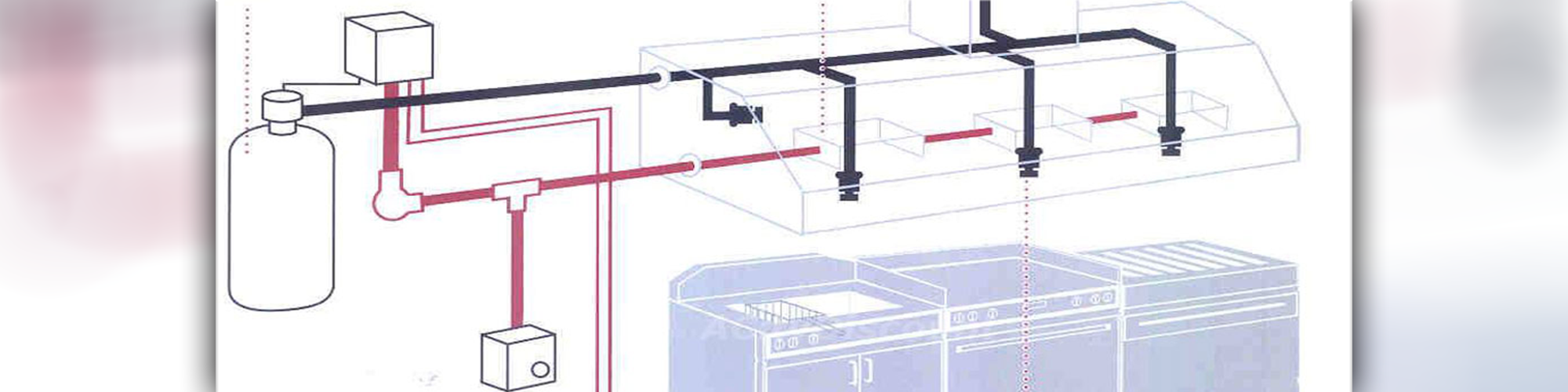

Kitchen Hood Fire Suppression System

These days, cooking in commercial kitchens is more dangerous than ever. Higher efficiency stoves and grills are capable of reaching much higher temperatures, and vegetable-based oils now commonly used for frying get much hotter than animal products and retain their heat much longer. At Advanced Fire Services, our commercial kitchen hood inspection process is geared toward keeping your restaurant in operation. If our technician inspects your commercial kitchen hood and finds any deficiencies, we will process the non-compliance information and get you a proposal right away so that you can get back to business as soon as possible.

The Kitchen Hood Inspection Process

Advanced Fire Services provides total system expertise for all of your kitchen fire suppression needs. Our in-house kitchen fire suppression system experts bring together all the elements you need for fully integrated kitchen hood ventilation and fire protection systems in your commercial kitchen. During your kitchen fire suppression inspection, our trained professionals will:

- Visually inspect conduit and location of appliance, duct, and plenum nozzles

- Inspect link line and position of detectors

- Inspect the automatic actuation of the fire system by cutting a terminal test link

- Test the remote pull station

- Verify electric and gas shuts off when the system is activated

- Replace fusible links and center link housings

- Verify the gauge on pressurized tanks is at the proper level

- Internal inspection of non-pressurized tanks for corrosion.

- Examine cylinders to record and verify the hydro test date

- Examine the regulator to record and verify the test dates

- Replace system cartridges when required by manufacturer (this is done at an additional charge)

- Remove and clean nozzles to ensure they are not clogged and replace nozzle caps

- Test all electrical interlocks (electric shut-offs and fan interlock requirements vary by local AHJs)

- Inspect the piping and copper tubing for tightness

- Record any obvious deficiencies discovered during the inspection